Virtual Seminar"Additive Manufacturing of Microfluidics – 3D Printing Techniques for Cleanroom-Free Fabrication, from FDM to VAT and Beyond"Benjamin Hedit

Date

Location

Description

Micro/Bio/Nanofluidics (Shen) Unit would like to invite you to the virtual seminar by Dr. Benjamin Hedit on February 9 (Monday).

----------------------------------------------------------------------

Date: Monday, February 9, 2021 (Monday)

Time: 16:00-17:00

**Zoom session

----------------------------------------------------------------------

*Zoom information

Join Zoom Meeting

https://oist.zoom.us/j/97236518980?pwd=TWM2TTUreUVYTW01OFFIdnZXN25yQT09

Meeting ID: 972 3651 8980

Passcode: 845757

Speaker:

Kari Dalnoki-Veress

Department of Physics & Astronomy, McMaster University, Hamilton, ON, Canada

Gulliver Laboratory, ESPCI ParisTech, PSL Research University, Paris, France

Title:

Additive Manufacturing of Microfluidics – 3D Printing Techniques for Cleanroom-Free Fabrication, from FDM to VAT and Beyond

Abstract:

3D-printing made huge leaps of progress within the last decade. Commercially available machines are now capable of impressive print-quality while at the same time being very affordable, with current entry-level FDM printer starting at around 100 $ and VAT printer at 300 $. These developments are a focus of interest in microfluidics, as 3D printing shows great promise in reducing or replacing work intensive cleanroom manufacturing methods and lowers the point of entry into microfluidic manufacturing. Furthermore the capabilities of 3D-printing allow for 3-dimensional microfluidic circuits, opening up new applications for example in 3D cell culture or Point-of-Care devices.

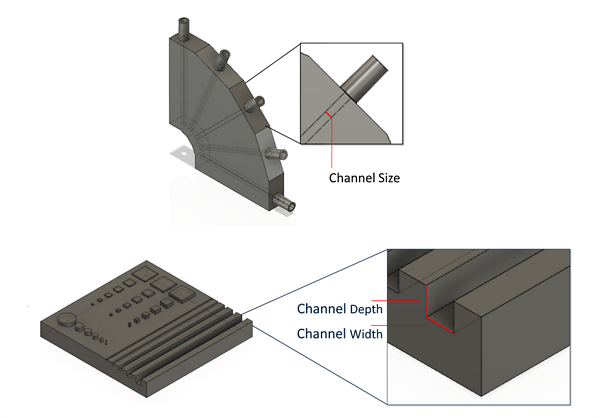

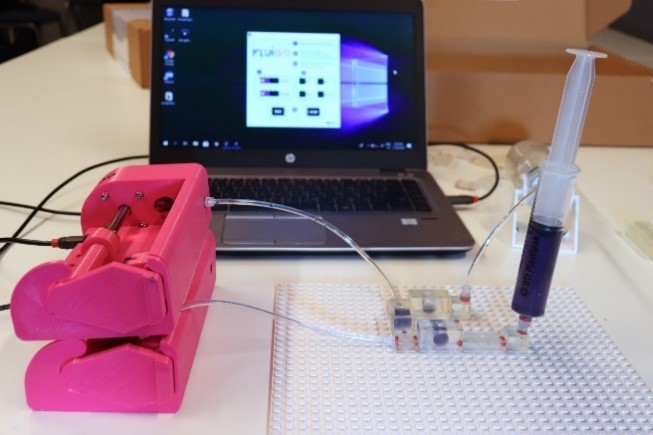

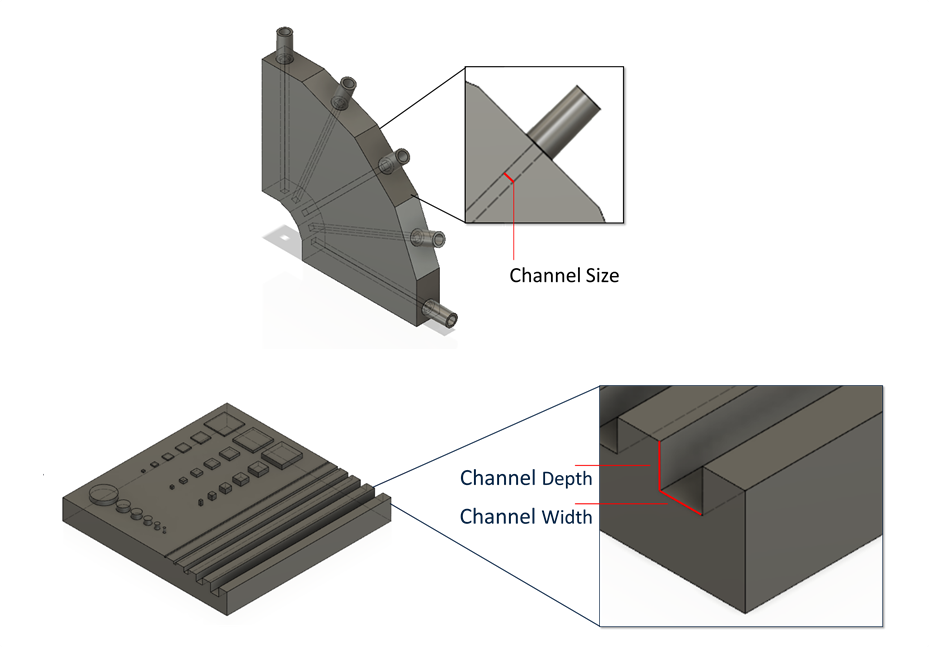

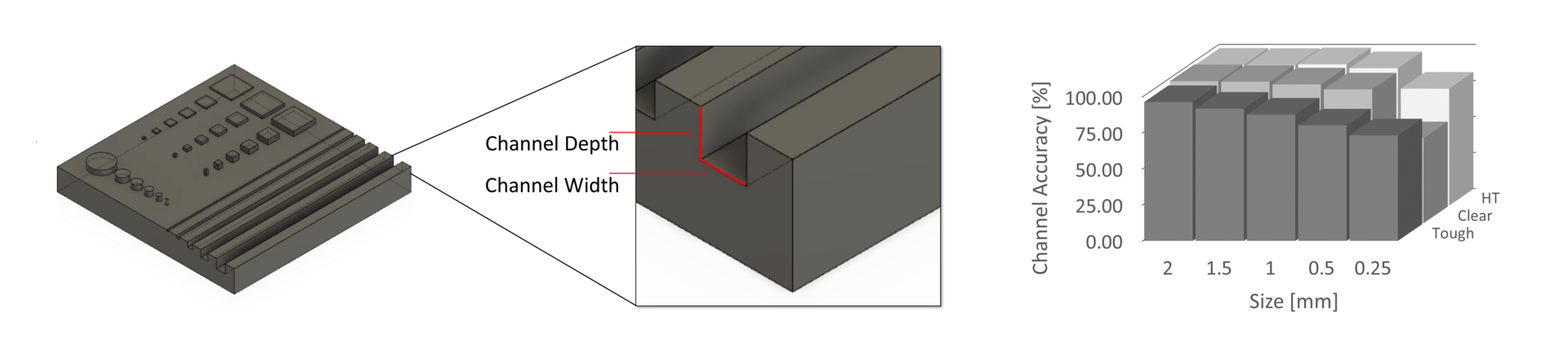

We discuss the capabilities of several different techniques of 3D-printing technology for the construction of microfluidic channels. We start with the cheapest and most straightforward way, FDM printing, which nonetheless opens up interesting possibilities, for example in the form of sacrificial channel construction. VAT printing on the other hand is more expensive but also benefits from a better resolution and shape accuracy. With the example of the commercial benchtop 3D-printer From 2, the manufacturing of microfluidic channels in terms of internal constructed channels, openly constructed channels and 3D prints as molds for PDMS will be demonstrated. The advantages of 3D-printing in microfluidics are exemplified with our Flui.Go Science Kit, which started out as a modular biochip project and turned into an award winning science education tool. It consists of LEGO-like building blocks with different circuit elements that can be assembled in a various ways to create microfluidic circuits.

3D printing for microfluidics also comes with downsides, foremost the danger of clogged channels due to leftover resin from the manufacturing process, which is more prominent with the very small channels needed for microfluidic applications. Therefore we developed a novel combinatorial process for the construction of 3-dimensional microchannel, the new process keeps the benefits of 3D manufacturing but reduces the downsides, with a two stage process. The process is easy and straightforward, requires minimal investment and allows the adaption of microfluidic circuits to a wide array of applications.

Host:

Prof. Amy Shen

Subscribe to the OIST Calendar: Right-click to download, then open in your calendar application.