FY2020 Annual Report

Nonlinear and Non-equlibrium Physics Unit

Associate Professor Mahesh M. Bandi

Abstract

We are an experimental group with primary interests in nonlinear and non-equilibrium physics, both applied and fundamental. Our work often intersects with soft matter physics, applied mathematics, mechanics, and their application to biologically inspired problems. Our current focus is trained towards problems in interfacial fluid dynamics, granular solids, biomechanics of the human foot and fluctuations in renewable energy sources.

1. Staff

- Dr. Fabienne Ziadi, Postdoctoral Scholar

- Ms. Ayano Sakiyama, RUA

- Mahesh Bandi, Associate Professor

2. Collaborations

2.1 Solar photovolatic power fluctuations

- Description: An analysis of the character of power fluctuations in solar photovoltaic power at the scale of a single solar panel, a solar plant, and at the grid scale.

- Type of collaboration: Joint research

- Researchers:

- Prof. Golan Bel, Ben Gurion University of the Negev, Israel.

- Prof. Mahesh Bandi, Nonlinear and Non-equilibrium Physics Unit, OIST Graduate University

2.2 Biomechanics of Mudskipper locomotion

- Description: Experimental study of the biomechanics underlying the various modes of mudskipper locomotion.

- Type of collaboration: Joint research

- Researchers:

- Dr. Fabienne Ziadi, Nonlinear and Non-equilibrium Physics Unit, OIST Graduate University

- Prof. Madhusudhan Venkadesan, Department of Mechanical Engineering and Materials Science, Yale University.

- Prof. Shreyas Mandre, Mathematics Institute, Warwick University, UK.

- Prof. Mahesh Bandi, Nonlinear and Non-equilibrium Physics Unit, OIST Graduate University

3. Activities and Findings

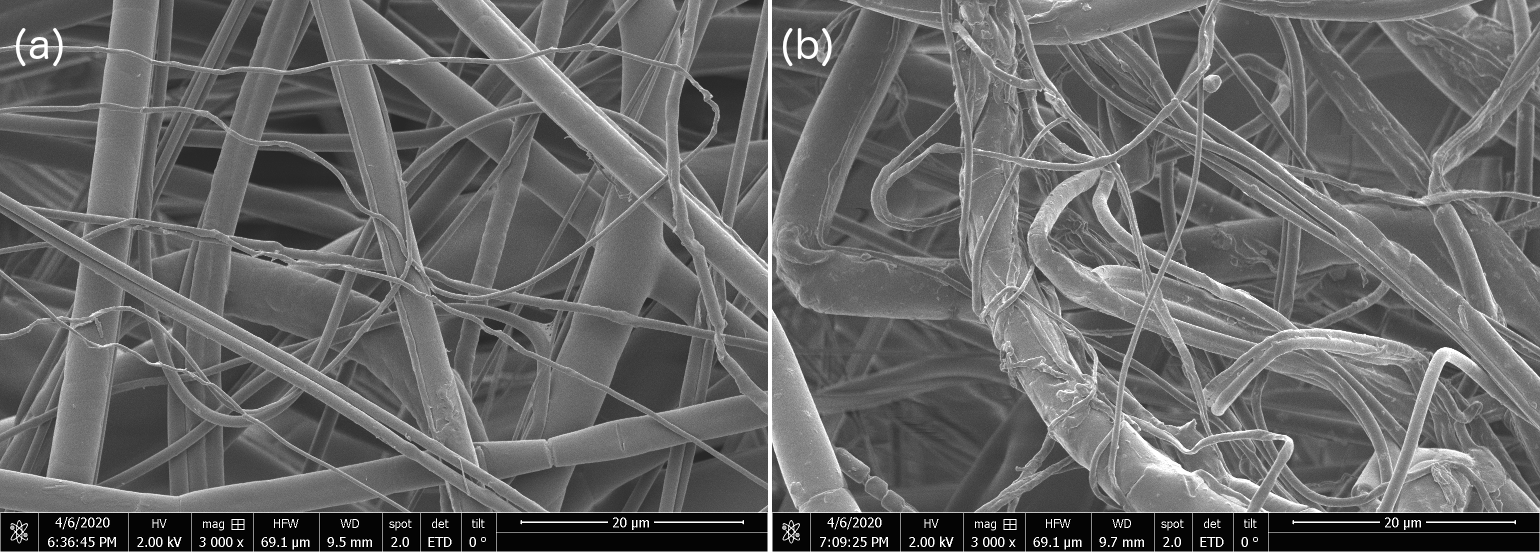

3.1 Electrocharged filtration layers from common materials and methods

The ongoing COVID-19 pandemic has witnessed multi-fold increase in face mask use for protection against viral infection, with many countries now mandating face masks in public areas. This sudden demand surge has created a scarcity of face masks, necessitating homemade cloth mask fabrication. But neither homemade cloth masks nor surgical masks are designed to protect against the SARS-Cov-2 virion, only respirators conforming to N95 or higher standard are rated for such protection. This capability of N95 filtering facepiece respirators (FRs) is owed primarily to an electrocharged filtration layer among other notable design features, deemed the most efficient among various particle filtration methods employed in face masks.

Taken together, these features permit filtration of more than 95% of particles of size greater than or equal to 0.3 microns under test standards designated by the US National Institute for Occupational Safety and Health (NIOSH) for N95 (US: NIOSH-42C-FR84) and its counterparts, including FFP2 (Europe: EN149-2001), KN95 (China: GB2626-2006), P2 (Australia and New Zealand: AS/NZ1716:2012), Korea 1st class (South Korea: KMOEL-2017-64), and DS2 (Japan: JMHLW-Notification214 from year 2018) facepiece respirators. Unfortunately, the electrocharged polymer filtration layers used in these FRs are manufactured through industrially sophisticated processes that are hard to duplicate using commonly available materials or methods.

This work details a process to fabricate electrocharged polymer based fabric using commonly available materials and easily replicable methods. The fabrication setup is based on the Cotton Candy (CC) principle, also known as rotary jet spinning or centrifugal spinning method. The primary control parameters for the CC method are translated to practical design rules for either the construction of a fabric manufacturing setup from common parts, or through minimal modification of commercial cotton candy machines. Practical solutions to tune the control parameters for fabrication of electrocharged polymer fabrics are also specified. Finally, characterisation of electrocharged fabrics made using the CC method for structural as well as filtration properties using two mask designs are presented.

Figure 1: Scanning electron micrographs for an electrocharged filtration layer from (a) cotton candy machine and (b) a commercial N95 filtering facepiece respirator.

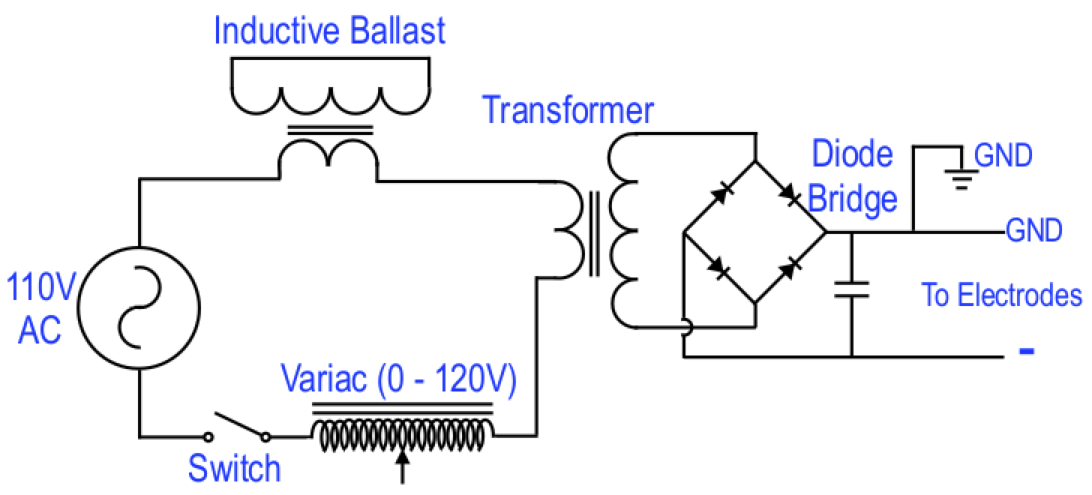

3.2 Electrocharging face masks using Corona Discharge Treatment

The COVID-19 pandemic has resulted in large-scale demand for N95 facepiece respirators (FRs) among essential personnel and face masks (FMs) within the larger populace. Supply chain disruptions in the pandemic's early days necessitated innovative methods to decontaminate and reuse personal protective equipment. This was especially true for single use non-woven polymer based FRs and surgical FMs, in turn leading to widespread adoption of wash-and-reuse cloth-based FMs for non-essential personnel. However, non-woven polymer electret fabrics form the mainstay for reliable filtration, especially in N95 FRs as they achieve high filtration efficiency with electrocharged filtration. Most surgical, non-woven polymer based FMs and standard cloth-based FMs do not possess this electrocharged filtration capability. Even in case of N95 FRs, repeated decontamination and re-use degrades electric charges and reduces filtration efficiency. These considerations highlight the need for methods to charge FMs or re-charge FRs and FMs in a quick and reliable manner. Accordingly, various methods such as triboelectric charging of FMs and exposing N95 FRs to high voltage electric fields have been reported.

Figure 2: Basic circuit diagram of the corona discharge treatment (CDT) system.

In this work, we developed a method to embed electric charges in a wide variety of fabrics (both natural and synthetic) using corona discharge from dielectric breakdown of air at atmospheric pressures, henceforth referred to as Corona Discharge Treatment (CDT). Our goals for this work are twofold:

1) Develop simple CDT system designs using common parts. Two designs, one using microwave oven parts and the other a neon sign power supply, are presented.

2) The ability to electrocharge non-woven, electret polymeric fabrics is well known. We wondered if knitted cloth fabrics too can be charged since most face masks out there are cloth-based. We learned it is possible to impart charges in some fabrics and within a limited range of parameters.

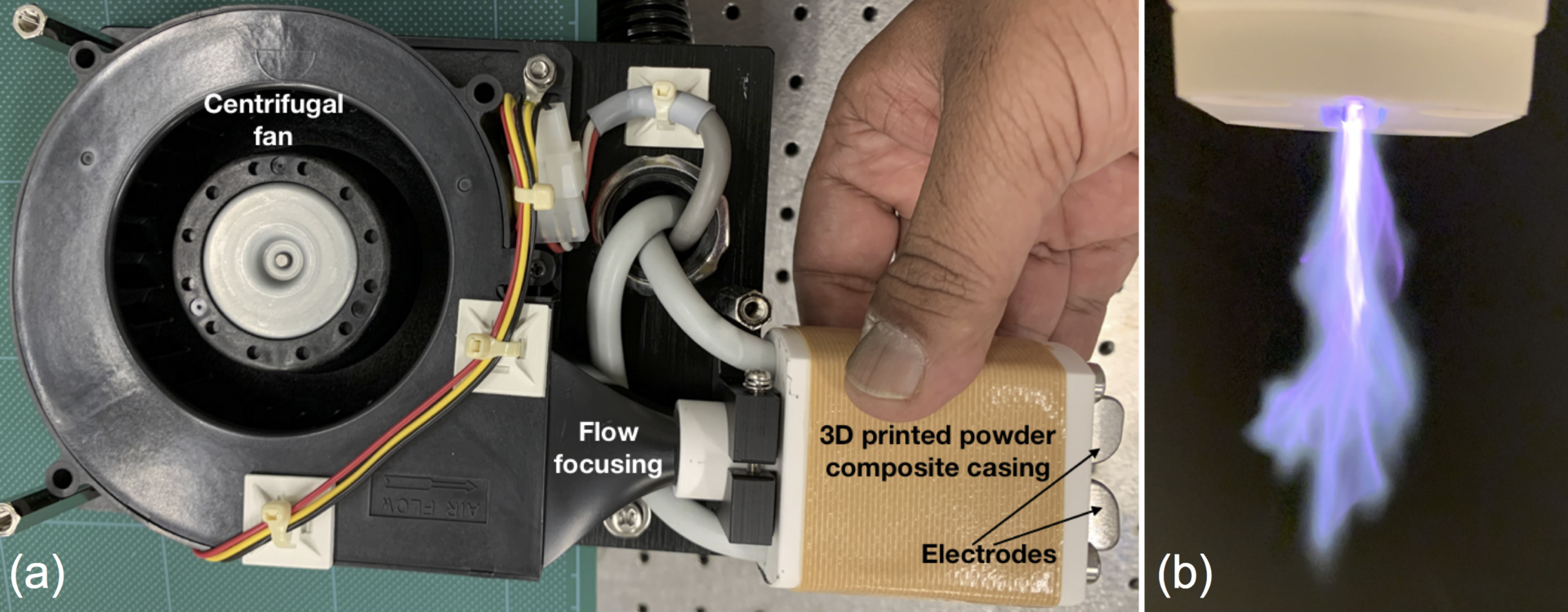

Figure 3: (a) Electrode system showing the centrifugal fan with flow focusing nozzle whose tapered conic section terminates at one (left) end of a 3D printed casing made from heat insulating powder composite and houses the electrodes at the other (right) end. (b) Snapshot of the corona discharge's transverse jet of electric wind exiting from the electrode end of the 3D printed powder composite casing.

4. Publications

4.1 Journals

- M. M. Bandi. Electrocharged facepiece respirator fabrics using common materials, Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences,476(2243),20200469 (2020-11-25) , The Royal Society , info:doi/10.1098/rspa.2020.0469

- Ziadi-Künzli, F., Soliman, T., Imai, H., Sakurai, M., Maeda, K., & Tachihara, K. (2020). Re-evaluation of deep-sea dogfishes (genus Squalus) in Japan using phylogenetic inference. Deep Sea Research Part I: Oceanographic Research Papers, 160, 103261.

4.2 Books and other one-time publications

Nothing to report

4.3 Oral and Poster Presentations

Nothing to report

5. Intellectual Property Rights and Other Specific Achievements

"Grid scale fluctuations and forecast error in Wind power", MM Bandi. Patent No.: WO2016/136237

6. Meetings and Events

6.1 Scientists’ insights on COVID- Where we are, how we got here, and where we are going?

- Date: May 15, 2020

- Venue: Webinar, International House of Japan: https://www.i-house.or.jp/eng/programs/asxaccj_joint_webinar_20200515/

- Speakers: Dr. Peter GRUSS (President and CEO, OIST), Dr. Mary COLLINS (Provost, OIST), Prof. Mahesh BANDI (Associate Professor, OIST)

6.2 Masking it up: electrocharged face piece respirator fabrics using common materials and simple methods.

- Date: June 22, 2020

- Venue: Online, International Centre for Theoretical Sciences colloquium: https://www.icts.res.in/colloquium/2020-06-22/mahesh-m-bandi

- Speaker: Prof. Mahesh BANDI (Associate Professor, OIST)

6.3 Business as (Un)usual:Scientific and Business Perspectives on COVID-19 [Day1]

- Date: June 23, 2020

- Venue: Webcast, the Asia Society New York, in association with the OIST Foundation: https://www.oist.jp/event/webcast-business-unusual-scientific-and-business-perspectives-covid-19-day-1

- Speakers: Prof. Mahesh Bandi, Dr. Faisal Mahmood, Prof. Amy Shen, Prof. Matthias Wolf

7. Other

Nothing to report.