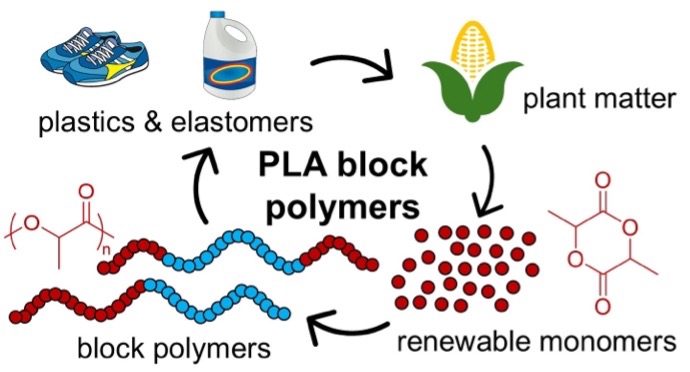

[Seminar] "Renewable, Recyclable, and Remarkable Aliphatic Polyester Block Polymers as Sustainable Plastics and Elastomers" by Prof. Marc Hillmyer, University of Minnesota

Date

Monday, March 24, 2025 - 10:30 to 11:30

Location

Seminar Room L4E48

Description

"Renewable, Recyclable, and Remarkable Aliphatic Polyester Block Polymers as Sustainable Plastics and Elastomers"

Speaker:

Professor

Department of Chemistry

Center for Sustainable Polymers

University of Minnesota

Abstract:

Sustainable polymers must be the future. A working definition of a sustainable plastic is one that is produced from renewable or recovered or waste feedstocks using energy efficient processes that minimize water use, greenhouse gas emissions, and other forms of pollution. Over its life cycle, a sustainable plastic generates negligible amounts of waste and can be practically recycled, reprocessed, or reclaimed after use. A full life cycle assessment of a new sustainable polymer technology is thus critical to make informed decisions about the potential integrated benefits for society. In early stages of sustainable polymer development, this is often not possible given the focus on the research required to move a potential technology forward. However, there is a clear need to address at least four major questions when developing new sustainable polymers: where do the polymers come from, how are they made, how do they perform in use, and what are sensible end-of-use scenarios. Promoting a circular economy depends critically on the answers to all these questions. With these combined aspects in mind, in this presentation I will emphasize our work on aliphatic polyester block polymers for resilient elastomers and tough plastics with an emphasis on addressing these questions in a holistic manner. Solutions to the global plastics predicament require such comprehensive investigations to practically realize the next generation of sustainable plastics. The main components I will emphasize in this work are the various forms of polylactide (i.e., amorphous and semi-crystalline) combined with amorphous, low glass transition temperature aliphatic polyesters prepared from alkyl-substituted caprolactones and valerolactones in various ways. I will cover strategies for controlled block polymer synthesis, fundamental structure property relationships, their degradation behavior, and how then can be effectively recycled through depolymerization. Targeted applications include (i) tough plastics for packaging, and (ii) highly recoverable rubbers for adhesives, polyurethane elastomers, and thermoplastic elastomers.

All-OIST Category:

Subscribe to the OIST Calendar: Right-click to download, then open in your calendar application.