Seminar "Advances in the analysis of metal sheet laser forming processes" by Prof. Diego Celentano

Date

Location

Description

[Speaker]

Prof. Diego Celentano

Professor of Engineering

Pontifical Catholic University of Chile, Santiago, Chile

[Abstract]

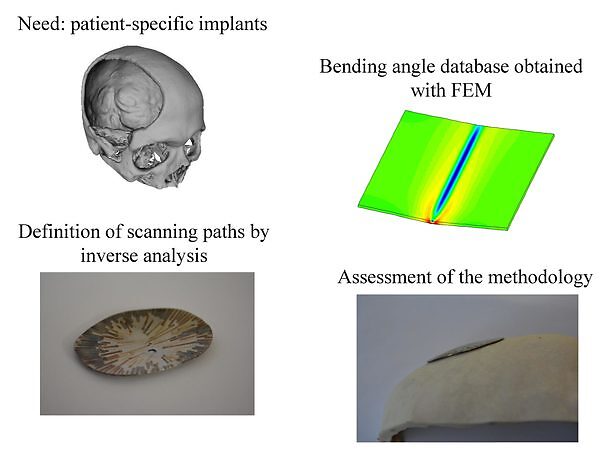

Laser forming is a tool-less sheet bending technique that induces thermal stresses in a workpiece by irradiation of a laser beam which, due to a rapid and localized heating, induces a plastic deformation under a compressive stress field. In the cooling stage, the workpiece shrinks, which leads to the development of bending or shape change in the region of the piece that has been irradiated. In comparison to traditional forming methods, the laser forming allows flexibility in the design of complex shapes that cannot be easily achieved by conventional methods and possibility to deal with non-metallic materials. This forming process been investigated and developed during the last years and, with the advent of the laser technology, its application to sheet forming has become a non-traditional emerging tool in the development of modern methods of manufacture. Its use in industry is advantageous to small production levels, as it allows eliminating the costs involved in the use of tools and reducing operating times. Laser forming has innovative applications in aerospace, marine and automotive sectors.

The aim of this talk is to present recent advances in the analysis of metal sheet laser forming processes, particularly addressing thermomechanical modeling, numerical simulation and experimental validation of different applications that involve a wide range of operating conditions. It is shown that the accurate prediction of the degree of bending in the workpiece using general irradiation paths allows the definition of controlled forming conditions that lead to the manufacture of a desired shape. In this context, the final industrially relevant outcome of this research is focused on the effect of general scan patterns as an additional operating variable to make the sheet laser forming a more flexible and reliable manufacturing process and, therefore, becomes a real alternative to traditional forming methods, especially for low-volume production and rapid prototyping of sheet metal components with final complex geometrical shapes.

Subscribe to the OIST Calendar: Right-click to download, then open in your calendar application.