FY2018 Annual Report

Biological Systems Unit

Professor Igor Goryanin

Abstract

For last years, the Biological Systems Unit has been engaged in development of BioElectrochemical System (BES)/Microbial Fuel Cell (MFC) technology for wastewater treatment. The BES/MFC applies complex interactions between microbial populations and electrodes to remove organics and to generate electricity, merging basic and applied goals of our Unit. By utilizing biological, chemical, engineering, and bioinformatics approaches, the Unit seeks to improve BES/MFC systems for better treatment efficiencies and electricity generation by understanding and building ideal microbial communities and developing cost-effective materials. Sustainable wastewater treatment is especially important for small islands like Okinawa.

One of the challenges of this technology is scaling up. The Unit has been working with a local Awamori (Okinawa unique spirit) distillery for the past seven years to treat rice wash and distillery wastewater and the world largest scaled-up reactor was constructed using our patented proprietary ion exchange membranes and catalysts. The project was funded by Japan Science and Technology Agency (JST). The unit received two grants from Okinawa Prefecture Government to develop technologies to 1) remove nitrogen and phosphate from swine wastewater using BES systems to meet the discharge level and 2) develop methods for bioremediation to clean anaerobically diesel-contaminated groundwater. The MFC/BES system was also utilized to remove organic acids to allow recycling of bioethanol process water (thin stillage water) in collaboration with COFCO, China. The development of a software called Advanced metagenomic Sequence Analysis in R (ASAR) allowed simultaneous analysis and visualization of taxonomy and metabolic pathways from metagenome data to understand and improve complex microbial communities. Our international collaboration also extended with the U.S., Russia, the U.K., Thailand and Hungary.

1. Staff

- Dr Igor Goryanin, Professor

- Dr. Mami Kainuma, Group Leader

- Dr. Slava Fedorovich, Staff Scientist

- Dr. Peter Babiak, Staff Scientist

- Dr. Lukasz Szydlowski, Postdoctoral Fellow

- Dr. Anna Prokhorova, Postdoctoral Fellow

- Mr. David Simpson, Technical Staff

- Mr. Tomoharu Inoue, Technical Staff

- Dr Marsel Murzabaev, Technical Staff

- Mr. Geoffrey Schaffer-Harris, Technical Staff

- Dr. Marina Khandarkhaeva, Research Assistant

- Ms. Rie Hiyane, Research Assistant

- Ms. Shizuka Kuda, Research Unit Administrator

2. Collaborations

2.1 A microbial fuel cell-based system for winery wastewater reuse (USA)

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Professor Michael F. Cohen, Sonoma State University, USA

- Professor Farid Farahmand, Sonoma State University, USA

2.2 Treatment and electricity generation of pineapple processing wastewater using microbial fuel cells (MFCs) (Thailand)

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Dr. P. Panichnumsin, King Mongkut’ University of Technology Thonburi, Thailand.

- Dr. C. Waewsak, King Mongkut’ University of Technology Thonburi, Thailand.

- Dr. S. Kalappanulak, King Mongkut’ University of Technology Thonburi, Thailand.

- Dr. T. Saithong, King Mongkut’ University of Technology Thonburi, Thailand.

2.3 Performance of Pilot-Scale Plug Flow Microbial Fuel Cell for Sustainable Wastewater Treatment and Energy Recovery (UK)

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Ourania Dimou Heriot Watt University, Edinburgh, UK.

- Prof Alan Harper, Heriot Watt University, Edinburgh, UK

2.4 Microbial Fuel Cells recycling of ethanol fermentation wastewater

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Dr. Bo Chen, Assistant Director of Biotechnology Center, COFCO Nutrition and Health Research Institute Co. Ltd, Bejing, China

2.5 Development of Microbial Fuel Cell-based technologies for wastewater treatment and characterization

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Dr. Gábor Márk Tardy, Budapest University of Technology and Economics

- Dr. Miklós Gyalai-Korpos, BES Europe Ltd. / PANNON Pro Innovations Ltd.

2.6 Biology of Microbial Fuel Cells and development of a software, Advanced metagenomic Sequence Analysis in R (ASAR)

- Description: Details and description of the collaboration, if necessary.

- Type of collaboration: Joint research

- Researchers:

- Professor Anatoly Sorokin, Institute of Biophysics, RAS, Puschchino, Russia

3. Activities and Findings

3.1 Bioelectrochemical Systems (BES): Material development, applications, scaling up and microbial metagenomic

The following projects are dedicated to improving our BES technology, including development of cost-effective bioreactor materials, widening possible applications of our technology, including scaling up and understanding microbial communities.

3.1.1 Development of New Eco wastewater treatment system utilizing microbial fuel cell (Mizuho Shuzo awamori distillery wastewater)

After long-term operation (5 years) of a pilot-scale (60 L x 3) MFC systems at local Awamori distillery to treat rice wash and distillery wastewater, we started a project to develop and test a high-rate biological wastewater treatment technology that meets the demanding criteria of SMEs using scaled-up MFC. Some of the universal challenges for any on-site treatment technology include ensuring the affordability of the equipment by the end-users, and competitive operation costs over the lifetime of the installation.The project involved four challenges. First, to develop an effective method to scale up our proprietary electrode materials, which had already been tested at lab scale. Second, to test electrode and treatment stability under extreme conditions that could be encountered on-site. Third, to construct and evaluate a large modular system using our electrode system under real world conditions, and finally to establish market receptiveness and commercial viability of the technology. The scaled-up reactor was constructed and deployed on-site in 2018 and has extensively monitored with current generation and organic removal. During a 6-month period, oraganic removal from rice wash wastewater for inlet concentration ranging from 4-8 g/L COD has been measured, ranging from 90-97% removal with hydraulic retention time (HRT).

This project was supported and reviewed by Japan Science and Technology Agency (University-initiated New Industry Creation Program, Project Support Scheme (START fund). and was collaborated with Bio-Sight Capital.

3.1.2. Novel strain isolation and metabolic engineering of the electrogenic bacterium, Arcobacter butzleri.

In this proof-of-concept study, we isolated a Arcobacter butzleri strain OK1 from inoculum in Okinawa, which was identified as Arcobacter butzleri, a known electrogenic species (Fedorovich et al. 2009). Electrogenic bacteria metabolize organic substrates by transferring electrons to the external electrode, with subsequent electricity generation. Using CRISPR/Cas9 and Cpf1, we engineered mutants with knockouts in either the acetate or lactate metabolic pathways, limiting their metabolism to a single carbon source. We demonstrated that it is possible to engineer substrate-specific bacteria that can be utilized as live biosensors using bioelectrochemistry.

3.1.3. R&D on swine wastewater treatment technology for simultaneous removal of nitrate and organics using bioelectrochemical systems (BES)

The volume of wastewater produced by intensive pig farming in Okinawa surpasses the available capacity for treatment and recycling. Removal of nitrate from wastewater is a worldwide concern due to its negative effects on human and environmental health. Currently the nitrate-nitrogen discharge limit for livestock wastewater receives special measure (500 mg/L) but very near future it will be lower to the general discharge standard (100 mg/L) to meet all other industries.

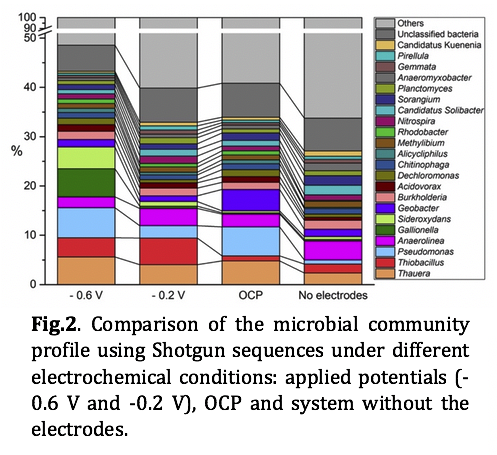

Continued from FY2017, we established lab-scale 2-L biocathode BES to simultaneously treat organics and nitrate in real swine wastewater. The full-strength raw wastewater containing high organic and volatile fatty acid levels(responsible for malodor) that are oxidized by the microbial community in the anode chamber. Electrons are transferred to the cathode chamber, where nitrate from aeration-treated wastewater (nitrified) serves as an electron acceptor and is to dinitrogen by denitrification via the cathodic microbial community to the general discharge standards. Through metagenome analysis, the cathode under applied potential (-600 V) was enriched by autotrophic denitrifying bacteria capable of accepting electrons from electrodes. The scaled-up reactors were designed to install on-site.

Continued from FY2017, we established lab-scale 2-L biocathode BES to simultaneously treat organics and nitrate in real swine wastewater. The full-strength raw wastewater containing high organic and volatile fatty acid levels(responsible for malodor) that are oxidized by the microbial community in the anode chamber. Electrons are transferred to the cathode chamber, where nitrate from aeration-treated wastewater (nitrified) serves as an electron acceptor and is to dinitrogen by denitrification via the cathodic microbial community to the general discharge standards. Through metagenome analysis, the cathode under applied potential (-600 V) was enriched by autotrophic denitrifying bacteria capable of accepting electrons from electrodes. The scaled-up reactors were designed to install on-site.

The project is funded by Okinawa Prefectural Government and conducted with a research body with Okinawa Environment Science Center, Okidoyaku and Okinawa Prefectural Livestock Research Center.

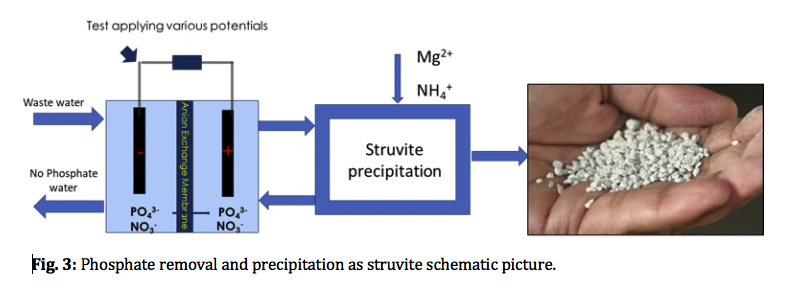

3.1.4. Phosphate removal and concentration from swine wastewater

The farming industry generates large amounts of wastewater that must be treated under special conditions to meet discharge regulations. As a result, many farms today are searching for cheap ways to effectively and sustainably treat wastewater. We use electrodialysis for removing excess phosphate ions from aerated swine waste water, and this method can be used for removing phosphate from any solution. Phosphate ions are transported through an AEM under the influence of an applied electric potential difference and are concentrated in the anodic chamber. We designed and built small scale prototype for phosphate removal from wastewater to test commercial membranes and OISTS developed membranes. A patent application on this technology to remove phosphate has been submitted.

3.1.5 R&D of Anaerobic Bioremediation Technology of Oil Contaminated Groundwater

We aim to establish in situ anaerobic bioremediation technologies, including bioelectrochemical systems, to treat diesel contaminated soil/groundwater using Okinawa specific soil types, Shimajiri Maji (cray and water permeable) and legal (cray and water impermeable).

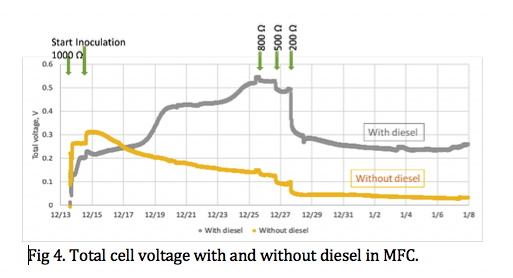

Oil-degrading microbial communities were enriched at the demonstration site (see FY2017 report) and used as inoculum to run groundwater diesel bioremediation with 6-L MFC reactors using proprietary electrode materials. We detected significant power generation in the presence of diesel as a sole carbon source (Fig. 4) and decreases in short-chain alkanes.

We participated in the project “Research and development of bioremediation technologies for heavy oil polluted soil and groundwater by prefectural microorganisms” funded by Okinawa Prefectural Government and conducted by a consortium of Okinawa Environmental Science Center and National Institute of Technology, Okinawa College.

3.1.6 A microbial-fuel cell-based system for winery wastewater reuse

Collaborators: Professor Michael F. Cohen, Sonoma State University, and D’ Argenzio Winery at Santa Rosa, CA USA.

With limited freshwater in California, finding a means to recycle winery wastewater for other uses is necessary. The most energy-intensive portion of the treatment process is aerating the wastewater to facilitate microbial oxidation of organic compounds. We have partnered with a small winery in Santa Rosa, California to deploy a pilot MFC system for onsite treatment of wine wastewater. Wastewater flows from a 900-L pH-buffering tank to two MFCs, one (MFC2) that recycles back to the tank, the other of which (MFC1) trickles into a vermifilter for final polishing of the water before finally flowing by gravity to the landscaping. Results gathered from testing and optimization of this system will inform the development of full-scale MFC-based systems to treat winery wastewater to a level suitable for irrigation, while producing energy.

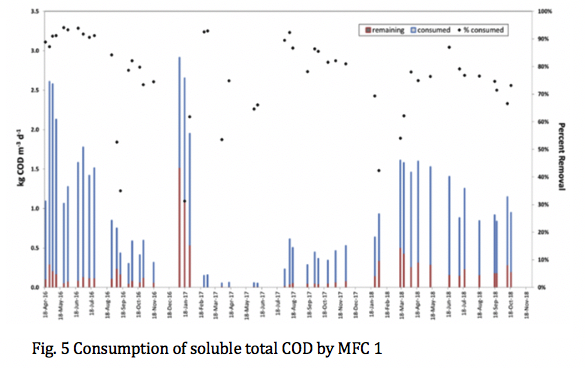

From August 2017 to October 2018, we analyzed performance of the system, maintaining the flow rate into the MFCs at a 6 d HRT. Passage of wastewater through MFC1 resulted in substantial organic removal, 75.2 ± 11.0% (mean ± SD, n = 23) of the total COD in the wastewater (Fig. 5). Most of the COD consumed from the wastewater went to the production of methane-rich biogas (133 ± 97 L m-3 d-1), while production of electrical power (35.1 mW/m3 in MFC1), though small, was a useful indicator of MFC health. Minimum daily air temperature had an effect on clearance of COD (F1, 24.52 =6.17, p < 0.02); as temperature increased, MFC performance increased.

From August 2017 to October 2018, we analyzed performance of the system, maintaining the flow rate into the MFCs at a 6 d HRT. Passage of wastewater through MFC1 resulted in substantial organic removal, 75.2 ± 11.0% (mean ± SD, n = 23) of the total COD in the wastewater (Fig. 5). Most of the COD consumed from the wastewater went to the production of methane-rich biogas (133 ± 97 L m-3 d-1), while production of electrical power (35.1 mW/m3 in MFC1), though small, was a useful indicator of MFC health. Minimum daily air temperature had an effect on clearance of COD (F1, 24.52 =6.17, p < 0.02); as temperature increased, MFC performance increased.

3.2. Databases, software and computational methods for systems biology

3.2.1 Software development for metagenome of bioelectrical systems

Collaborators: Professor Anatoly Sorokin, Institute of Biophysics, RAS, Russia. Dr Olga Vasieva, Ingenet Ltd., UK

Functional and taxonomic metagenomic analyses are critical steps in understanding interspecific interactions within microbial communities. Together with our collaborators we have developed a software package followed by manual curation to perform these analyses simultaneously. We have developed the ASAR DB Database, the interactive tool and databases for storage and exploratory analysis of unlimited metagenomic sequencing data along 3 dimensions: taxonomy, function, and environmental conditions, which can handle an unlimited amount of sequence information (Orakov et al. 2018a).

4. Publications

4.1 Journals

- Orakov, A., Sakenova, N. K., Sorokin, A., & Goryanin, I. (2018). ASAR: visual analysis of metagenomes in R. Bioinformatics, 34(8), 1404-1405. doi:10.1093/bioinformatics/btx775

- Orakov, A., Sakenova, N., Goryanin, I., & Sorokin, A. (2018). ASAR Database: An R Tool for Visual Analysis and Storage of Metagenomes. Paper presented at the In Proceedings of the 11th International Joint Conference on Biomedical Engineering Systems and Technologies

4.2 Books and other one-time publications

Nothing to report

4.3 Oral and Poster Presentations

- Szydlowski, L. Taxonomic and functional shifts in electrogenic microbial communities operating under suboptimal conditions within bioelectrochemical systems. JSME/ASME, 13th July 2018, Ginowan, Japan (invited speaker).

- Szydlowski, L., Lan, T.C.T., Goryanin, I. Live biosensor development using electrogenic bacteria with limited metabolism for substrate-specific detection. 5th SSBSS, Jul 2018, Certosa di Pontigiano, Italy (poster).

- Prokhorova, A., Kainuma, M., Hiyane, R., Sorokin, A., Vasieva, O., Kazeoka, M., Suzuki, N., Ninomiya, K. and Goryanin, I. Performance optimization of the electrotrophic denitrification for a sustainable treatment of nitrate-contaminated swine wastewater. Water and Environment Technology Conference, July 2018 (talk and poster hybrid)

- Kainuma, M., Prokhorova, A., Hiyane, R., Sorokin, A., Vasieva, O. Kazeoka, M. Suzuki, N., Ninomiya K. and Goryanin I., Nitrate removal from aeration-treated swine wastewater using a two-chamber biocathodic system. Japanese Society for Microbial Ecology, Okinawa, July 2018 (poster)

- Murzabaev, M., Kainuma, M., Babiak, P., Furuie, K., Tanabe, T., Yamaniha, Y. and Goryanin, I. Development of anaerobic bioremediation technology for oil groundwater and soil contamination in Okinawa. Symposium on Soil and Groundwater Contamination and Remediation, Fukushima, Japan, October 2018 (talk and poster hybrid)

- Prokhorova, A., Kainuma, M., Hiyane, R., Sorokin, A., Vasieva, O. and Goryanin, I. Bioelectrochemical denitrification at biocathodes using swine wastewater. 4th Asia Pacific International Society of Microbial Electrochemistry and Technology meeting (AP-ISMET), Goa, India, November 2018 (talk)

5. Intellectual Property Rights and Other Specific Achievements

- Process for preparing a supported catalytic material and supported catalytic material. PCT/JP2018/007294 Priority date: Feb. 28, 2017. Inventors: G. Schaffer-Harris, V. Fedrovich, I. Goryanin, L. Szydlowski, D. Simpson, G. Filonenko (OIST).

- Bioelectrochemical system with horizontal and vertical types of liquid flow for wastewater treatment (IDF-2018-003 in progress)

- Phosphate recovery from swine wastewater by electrodialysis (IDF-2018-011 in progress)

6. Meetings and Events

Nothing to report

7. Other

Outreach

- Event: Technology Startup Summit Program Simpson, D. Jun 20, 2018. OIST. Program description: 5-minute pitch event “Establishing a university startup” for Proof Of Concept MFC commercialization, sponsored by Beyond Next Ventures VC (around 40 people participated)

- Event: Symposium and panel discussion on the research development of environmentally sustainable technology using microorganisms. Kainuma, M. Jul 26, 2018. Okinawa Prefectural Museum, Naha, Okinawa. Organized by OPG

Introduced two OPG projects on swine wastewater and oil bioremediation. (Participated around 100 people from industries and academics. )

- Event: SCORE! Internship Program. Inoue, T. Aug 8, 2018. OIST

Program description: Seminar “Energy harvesting with Microbial Fuel Cell and wastewater treatment system in Awamori case” (around 20 people participated)

- Event: Nanjo City Hall visiting Mizuho Shuzo. Inoue, T. Sep 7, 2018. Mizuho Shuzo, Naha. Program description: The technical explanation and the OPG project were explained in Mizuho Shuzo where MFC was installed as a demonstration experiment machine.

- Event: Invited speaker to Nanyang Technological University/NEWRI. Szydlowski L. Sep 28, 2018. Singapore. Program description: Seminar “Metabolic pathway engineering as a tool to develop electrogenic microbial consortia for substrate-specific wastewater treatment, electrostimulated biosynthesis, and real-time water monitoring using Microbial Electrogenic Technology” given to students and staff at Nanyang Environment and Water Research Institute.

- Event: Okinawa Prefectural Industry Festival. Simpson D. Oct 19-20, 2018. Naha Ounoyama Park, Okinawa. Program description: The OIST booth was set up, and when the visitors were given an explanation of the research content, the project was explained to people who are interested in livestock wastewater treatment.

- Event: OIST Science Café. Simpson, D. Oct 26, 2018. Tokyo Black Aoyama, Tokyo

Contents Explanation of the livestock wastewater treatment in OIST research for newspaper and media.

- Event: Press Briefing Session. Simpson, D. Oct 26, 2018. Private Goblinpark, Tokyo

Program description: Introduction to our unit activities “Sustainable wastewater treatment: Affordable solutions for local industry and communities” 90-minute presentation and 40-minute Q&A. (10 journalists participated, 3 Cabinet Office members)

- Event: Invited speaker to National Taiwan University and National Taiwan Central University, Taiwan. Kainuma, M. Nov 19 and 20, 2018.

Program description: Title “Improving the efficiency of food and livestock wastewater treatment using bioelectrochemical systems” Talk given to graduate students of Department of Environmental Engineering.

- Event: Okinawa Venture Market Pitch event. Simpson D., Inoue, T. Dec 10, 2018. Okinawa Prefectural Industrial Support Center, Okinawa

Program description: Presentation on the livestock wastewater treatment.

- Event: 3rd TechPitch Okinawan. Simpson, D. Dec 10, 2018. Naha, Okinawa

Program description: Okinawa Venture Market pitch for “Sustainable wastewater treatment: Affordable solutions for local industry and communities.” (around 100 people participated)

- Event: OIST Science talk. Kainuma, M., Prokhorova, A. Dec 14, 2018. Junk-do bookstore, Naha, Okinawa

Program description: Public talk on “Eco-friendly wastewater treatment system using electrogene and other microorganisms” (around 40 people participated)

Newspaper and popular articles

- Newspaper company: Ryukyu Shimpo (Okinawa) (琉球新報)

Title: Wastewater treatment using microorganisms by OIST research team

Date: June 6, 2018

Brief description: Interviewed on scale-up MFC (1.7m3) reactor at Mizuho Distillery

- Newspaper company: Okinawa Times (Okinawa)(沖縄タイムス)

Title: Wastewater treatment technology development in OIST

Date: December 2, 2018

Brief description: Introduction of BES/MFC wastewater treatment project relevant to Okinawa and announcement of Science talk