FY2018 Annual Report

Energy Materials and Surface Sciences Unit

Abstract

Solar energy harvesting, energy storage, efficient lighting system, organic electronics, and fundamental studies by surface science techniques were the topics of investigation within this year in our research unit. On the topic of solar cell, stability is a major challenge and we have unraveled the photo- and thermal-decomposition in methylammonium lead halide perovskites and inferred design principles to increase photovoltaic device stability (Section 3.1). In addition, our hybrid chemical vapor deposition enabled us to up-scale solar modules with a designated area of 91.8 cm2 approaching 10% efficiency (Section 3.2). Organic transistor is one of the fundamental building-block unit in organic electronics. We showed the importance of interface engineering at the semiconductor/dielectric interface to improve device performance (Section 3.3). Efficient energy storage system is an important technological approach to manage society's power supply demands and create a reliable energy infrastructure in large scales. We have reported the performance improvement of lithium-ion transition metal oxide battery employing conducting polymer (Section 3.4).

We were involved in the organization of an international symposium.

Symposium Lead Organizer

2018 MRS Spring Meeting - Symposium EN02, “Advances in Perovskite Solar Cell Devices and Applications”

Phoenix, Arizona, USA

April 2 - 6, 2018.

1. Unit Members

• Ms. Naoko Ogura-Gayler, Research Unit Administrator

• Dr. Luis K. Ono, Group Leader

• Dr. Yan Jiang, Researcher

• Dr. Emilio J. Juarez-Perez, Researcher

• Dr. Taehoon Kim, Researcher

• Dr. Lingqiang Meng, Researcher

• Dr. Longbin Qiu, Researcher

• Dr. Zhifang Wu, Researcher

• Dr. Jeremy Hieulle, Researcher

• Dr. Sisi He, Researcher

• Mr. Zafer Hawash, OIST Graduate Student

• Mr. Collin C. Stecker, OIST Graduate Student

• Ms. Afsham Jamshaid, OIST Graduate Student

2. Collaborations

- Theme: Flexible and Stable LiS battery - Nat. Commun. 9, 4480 (2018).

- Type of collaboration: collaborative research

- Collaborator:

- Prof. Zijian Zheng, The Hong Kong Polytechnic University, Hong Kong SAR, China

- Theme: Atomic force microscopy on MAPbBr3 single crystals.

- Type of collaboration: collaborative research

- Collaborator:

- Prof. Jeong Young Park, Korea Advanced Institute of Science and Technology (KAIST), Republic of Korea.

- Theme: Fabrication of high performance organic field-effect transistors.

- Type of collaboration: collaborative research

- Collaborator:

- Prof. Yun Li, Nanjing University, PR China.

3. Activities and Findings

3.1 Stable perovskite solar cells/modules through deeper understanding on perovskite decomposition mechanisms and interfacial energy level alignment.

Emilio J. Juarez-Perez, Luis K. Ono, Maki Maeda, Yan Jiang, Zafer Hawash, and Yabing Qi*, "Photo-, Thermal-decomposition in Methylammonium Halide Lead Perovskites and inferred design principles to increase photovoltaic device stability" J. Mater. Chem. A 6, 9604-9612 (2018).

Shenghao Wang, Takeaki Sakurai, Weijia Wen*, and Yabing Qi*, "Energy Level Alignment at Interfaces in Metal Halide Perovskite Solar Cells" Adv. Mater. Interfaces 5, 1800260 (2018).

Luis K. Ono, Yabing Qi*, and Shengzhong (Frank) Liu*, "Progress toward Stable Lead Halide Perovskite Solar Cells" Joule 2, 1961–1990 (2018).

Zonghao Liu, Longbin Qiu, Emilio J. Juarez-Perez, Zafer Hawash, Taehoon Kim, Yan Jiang, Zhifang Wu, Sonia R. Raga, Luis K. Ono, Shengzhong (Frank) Liu and Yabing Qi*, "Gas-solid reaction based over one-micrometer thick stable perovskite films for efficient solar cells and modules" Nat. Commun. 9, 3880 (2018).

Nam-Gyu park*, Jinsong Huang*, and Yabing Qi*, "Themed issue on perovskite solar cells: research on metal halide perovskite solar cells towards deeper understanding, upscalable fabrication, long-term stability and Pb-free alternatives" Sustain. Energy Fuels 2, 2378-2380 (2018).

Jeremy Hieulle†, Xiaoming Wang†, Collin Stecker, Dae-Yong Son, Longbin Qiu, Robin Ohmann, Luis K. Ono, Aitor Mugarza, Yanfa Yan*, and Yabing Qi*, "Unraveling the impact of halide mixing on perovskite stability" J. Am. Chem. Soc. 141, 3515-3523 (2019). († equal contribution)

Zhifang Wu, Zonghao Liu, Zhanhao Hu, Zafer Hawash, Longbin Qiu, Yan Jiang, Luis K. Ono, and Yabing Qi*, "Highly Efficient and Stable Perovskite Solar Cells via Modification of Energy Levels at the Perovskite/Carbon Electrode Interface" Adv. Mater. 31, 1804284 (2019).

Emilio Jose Juarez-Perez*, Luis K. Ono, Iciar Uriarte, Emilio J. Cocinero, and Yabing Qi*, "Degradation mechanism and relative stability of methylammonium halide based perovskites analyzed on the basis of acid-base theory" ACS Appl. Mater. interfaces 11, 12586–12593 (2019).

Guoqing Tong, Taotao Chen, Huan Li, Wentao Song, Yajing Chang, Jingjing Liu, Linwei Yu, Jun Xu, Yabing Qi*, and Yang Jiang*, "High Efficient Hole Extraction and Stable All‐Bromide Inorganic Perovskite Solar Cells via Derivative‐Phase Gradient Bandgap Architecture" Solar RRL 3, 1900030 (2019).

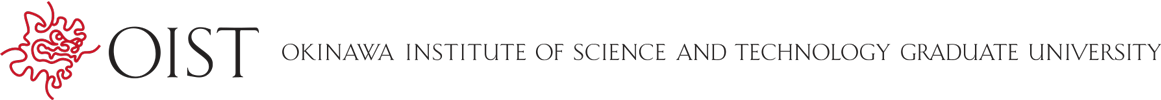

Stability is a major challenge facing the commercialization of perovskite solar cell technology. To address this issue, we studied the fundamental properties and fabrication techniques as parallel lines. We studied the basic properties of each stack inside a perovskite solar cells, especially for perovskite materials, from atomic scale. And reviewed the decomposition mechanisms of perovskite materials and energy level alignment of interfacial layers. Also a gas-solid reaction method was applied to fabricate high-quality perovskite film with full coverage, improved crystallinity and uniformity, the resultant PSCs achieve high PCE (19±0.4%) and excellent stability (T80 lifetime exceeding 1600 h under dry nitrogen environment) at the same time.

Figure 1: (Left one) Reviews the progress toward stable lead halide perovskite solar cells. (Right top one) reviews themed issue on perovskite solar cells: research on metal halide perovskite solar cells towards deeper understanding, upscalable fabrication, long-term stability and Pb-free alternatives. (Right bottom one) reviews the energy level alignment at interfaces in metal halide perovskite solar cells.

3.2 Scalable fabrication of perovskite solar cells/modules by chemical vapor deposition and combining method of spray coating and chemical vapor deposition.

Yan Jiang, Mikas Remeika, Zhanhao Hu, Emilio J. Juarez‐Perez, Longbin Qiu, Zonghao Liu, Taehoon Kim, Luis K. Ono, Dae‐Yong Son, Zafer Hawash, Matthew R. Leyden, Zhifang Wu, Lingqiang Meng, Jinsong Hu and Yabing Qi*, "Hybrid Chemical Vapor Deposition Enables Scalable and Stable Cs-FA Mixed Cation Perovskite Solar Modules" Adv. Energy Mater. 9, 1803047 (2019).

Longbin Qiu†, Sisi He†, Yan Jiang, Dae-Yong Son, Luis K. Ono, Zonghao Liu, Taehoon Kim, Theodoros Bouloumis, Said Kazaoui, and Yabing Qi*, "Hybrid Chemical Vapor Deposition Enables Scalable and Stable Cs-FA Mixed Cation Perovskite Solar Modules with a Designated Area of 91.8 cm2 Approaching 10% Efficiency" J. Mater. Chem. A 7, 6920-6929 (2019). († equal contribution)

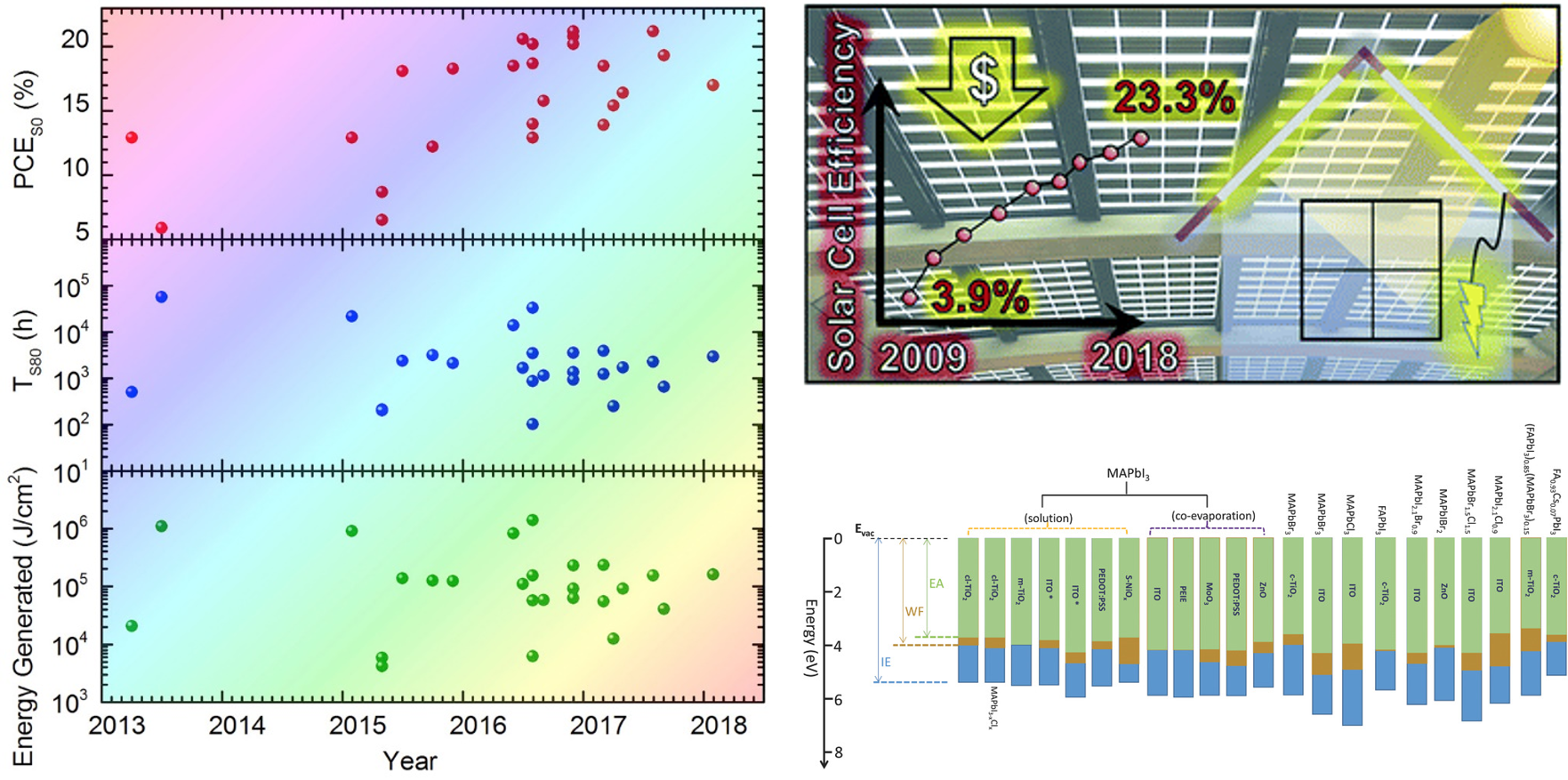

An upscalable perovskite film deposition method combining raster ultrasonic spray coating and chemical vapor deposition is reported. This method overcomes the coating size limitation of the existing stationary spray, single-pass spray, and spin-coating methods. In contrast with the spin-coating method (>90% Pb waste), negligible Pb waste during PbI2 deposition makes this method more environmentally friendly. Outstanding film uniformity across the entire area of 5 cm × 5 cm is confirmed by both large-area compatible characterization methods (electroluminescence and scattered light imaging) and local characterization methods (atomic force microscopy, scanning electron microscopy, photoluminescence mapping, UV–vis, and X-ray diffraction measurements on multiple sample locations), resulting in low solar cell performance decrease upon increasing device area. With the FAPb(I0.85Br0.15)3 (FA = formamidinium) perovskite layer deposited by this method, champion solar modules show a power conversion efficiency of 14.7% on an active area of 12.0 cm2 and an outstanding shelf stability (only 3.6% relative power conversion efficiency decay after 3600 h aging). Under continuous operation (1 sun light illumination, maximum power point condition, dry N2 atmosphere with <5% relative humidity, no encapsulation), the devices show high light-soaking stability corresponding to an average T80 lifetime of 535 h on the small-area solar cells and 388 h on the solar module.

The development of scalable deposition methods for stable perovskite layers is a prerequisite for the development and future commercialization of perovskite solar modules. However, there are two major challenges, i.e., scalability and stability. In sharp contrast to a previous report, here we develop a fully vapor based scalable hybrid chemical vapor deposition (HCVD) process for depositing Csformamidinium (FA) mixed cation perovskite films, which alleviates the problem encountered when using conventional solution coating of mainly methylammonium lead iodide (MAPbI3). Using our HCVD method, we fabricate perovskite films of Cs0.1FA0.9PbI2.9Br0.1 with enhanced thermal and phase stabilities, by the intimate incorporation of Cs into FA based perovskite films. In addition, the SnO2 electron transport layer (ETL) (prepared by sputter deposition) is found to be damaged during the HCVD process. In combination with precise interface engineering of the SnO2 ETL, we demonstrate relatively large area solar modules with efficiency approaching 10% and with a designated area of 91.8 cm2 fabricated on 10 cm×10 cm substrates (14 cells in series). On the basis of our preliminary operational stability tests on encapsulated perovskite solar modules, we extrapolated that the T80 lifetime is approximately 500 h (under the light illumination of 1 sun and 25℃.

Figure 2: (Left) Hybrid Chemical Vapor Deposition Enables Scalable and Stable Cs-FA Mixed Cation Perovskite Solar Modules. (Right) Hybrid Chemical Vapor Deposition Enables Scalable and Stable Cs-FA Mixed Cation Perovskite Solar Modules.

3.3 Interfacial flat-lying molecular monolayers for performance enhancement in organic field-effect transistors.

Qijing Wang, Sai Jiang, Longbin Qiu, Jun Qian, Luis K. Ono, Matthew R. Leyden, Xinran Wang, Yi Shi*, Youdou Zheng, Yabing Qi*, and Yun Li*, "Interfacial Flat-lying Molecular Monolayers for Performance Enhancement in Organic Field-Effect Transistors" ACS Appl. Mater. Interfaces 10, 22513-22519 (2018).

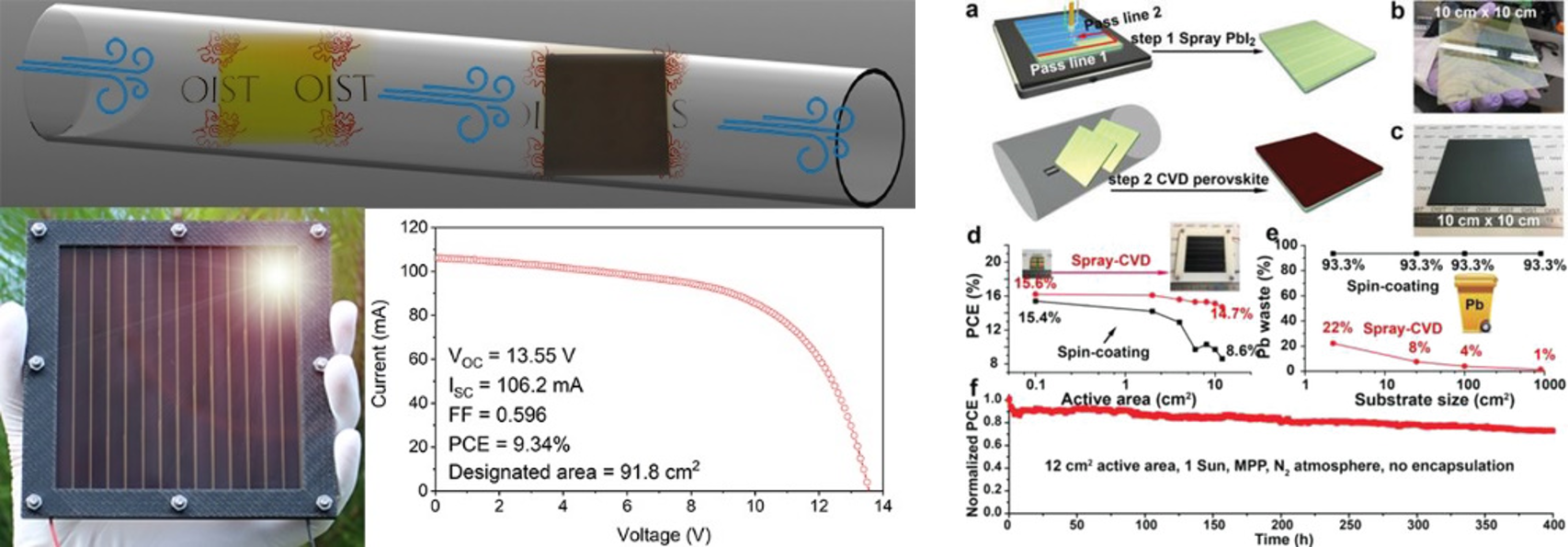

Organic field-effect transistors (OFETs) are the most fundamental device units in organic electronics. Interface engineering at the semiconductor/dielectric interface is an effective approach for improving device performance, particularly for enhancing charge transport in conducting channels. Here, we report flat-lying molecular monolayers that exhibit good uniformity and high crystallinity at the semiconductor/dielectric interface, deposited through slow thermal evaporation. Transistor devices achieve high carrier mobility up to 2.80 cm2 V−1 s−1, which represents a remarkably improvement in device performance compared with devices that are completely based on fast-evaporated films. Interfacial flat-lying monolayers benefit charge transport by suppressing the polarization of dipoles and narrowing the broadening of trap density of states. Our work provides a promising strategy for enhancing the performance of OFETs by using interfacial flat-lying molecular monolayers.

Figure 3: Density of trap states obtained from the FET data.

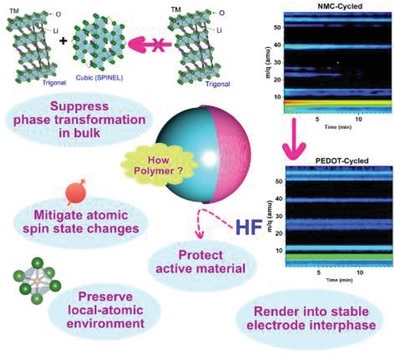

3.4 Elucidating the mechanism involved in the performance improvement of lithium-ion transition metal oxide battery by conducting polymer.

Taehoon Kim, Luis K. Ono, and Yabing Qi*, "Elucidating the Mechanism Involved in the Performance Improvement of Lithium‐Ion Transition Metal Oxide Battery by Conducting Polymer" Adv. Mater. Interfaces, 6, 1801785, (2019).

Surface treatments with conducting polymers are effective in ameliorating charge capacities and cycling performances for a wide range of lithium-ion batteries such as Li-layered transition metal oxide, Li-sulfur, and Li-air batteries. So far, however, very little is known about the key process directly involved with the improvement of cell performance and stability. The present study examines how a conducting polymer can contribute to charge capacity enhancement, employing poly(3,4 ethylenedioxythiophene):poly(styrenesulfonate) coating on the lithium-layered transition metal oxide cathode. The property of the electrode interface layer is studied on the basis of the local atomic environments. The conducting polymer not only hinders the formation of LiF, carbonates, and semicarbonates compounds but also renders the nature of the solid-electrolyte interphase layer formed during electrochemical cycles. Furthermore, it inhibits the dissolution of the active material into the electrolyte and preserves the initial atomic states including the active material bulk. The coating enables good consistency in the local atomic environment with depth at the electrode interface, which in turn impedes the phase mismatch resulting from the surface reconstruction on the layered oxide electrode. This further mitigates the phase transformation of the active material, resulting in a lower voltage decay on charge–discharge.

Figure 4: Schematics of surface condition of active material particles with corresponding SIMS position ion detection (PID) measurements under Ar-gas environment.

4. Publications

4.1 Journals

→Please see our publications page for published journals

4.2 Books and Other One-Time Publications

N/A

4.3 Oral and Poster Presentations

- Yabing Qi, “Perovskite Material and Solar Cell Research by Surface Science and Advanced Characterization", 2018 Materials Research Society (MRS) Spring Meeting & Exhibit, Phoenix, AZ USA, April 2–6, 2018. (Invited talk)

- Yan Jiang, “Up-scaling Cs-substituted Mixed Cation Perovskite Modules with High Stability and Efficiencies up to 14.6%", 2018 Materials Research Society (MRS) Spring Meeting & Exhibit, Phoenix, AZ USA, April 2–6, 2018.

- Taehoon Kim, “Stacked-graphene layers as engineered solid-electrolyte interphase (SEI) grown by chemical vapour deposition for lithium-ion batteries ", 2018 Materials Research Society (MRS) Spring Meeting & Exhibit, Phoenix, AZ USA, April 2–6, 2018.

- Luis K. Ono, “Up-Scaling of Organic-Inorganic Hybrid Perovskite Solar Cells and Modules", 2018 Materials Research Society (MRS) Spring Meeting & Exhibit, Phoenix, AZ USA, April 2–6, 2018.

- Yabing Qi, “Perovskite Material and Solar Cell Research by Surface Science and Advanced Characterization", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018. (Invited talk)

- Yabing Qi, “Instability of Lead Halide Perovskites", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018.

- Longbin Qiu, “Chemical Vapor Deposition for 10 cm x 10 cm Large-Area Perovskite Solar Modules", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018

- Longbin Qiu, “Interface Engineering to Improve Efficiency and Operational Lifetime of Perovskite Solar Cells", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018

- Zonghao Liu, “>1 um Thick High-Quality Stable Perovskite Films for High Performance Solar Cells and Modules with High Reproducibility", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018

- Luis K. Ono, “Spiro-MeOTAD Hole Transport Layer in Perovskite-based Solar Cells", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018

- Luis K. Ono, “Up-Scaling of Organic-Inorganic Hybrid Perovskite Solar Cells and Modules", 2018 Materials Research Society (MRS) Fall Meeting & Exhibit, Boston, MA USA, November 25–30, 2018

5. Intellectual Property Rights and Other Specific Achievements

N/A

6. Meetings and Events

- Date: December 5-8, 2018

- Venue: City University of Hong Kong

- Title: The 10th Asian Conference on Organic Electronics

- Date: November 25-30, 2018

- Venue: Boston, Massachusetts, USA

- Title: Materials Research Societry (MRS) Meeting

- Date: September 20-23, 2018

- Venue: Fudan University, Shanghai, China

- Title: the 2nd International Conference of Molecular Engineering of Polymers (MEP-2)

- Date: July 29, 2018

- Venue: Hefei, China

- Title: The 22nd International Conference on Photochemical Conversion and Storage of Solar Energy (IPS 22)

- Date: June 27-29, 2018

- Venue: Sungkyunkwan University, Korea

- Title: the 7th Sungkyun International Solar Forum (SISF2018)

- Date: April 2-6, 2018

- Venue: Phoenix, Arizona, USA

- Title: Materials Research Societry (MRS) Meeting

- Date: Jan 31, 2018

- Venue: Kitakyushu Science and Research Park

- Title: Workshop on Solar Light Energy Conversation Research